How aluminium is recycled

The consumer throws aluminium cans and foil into a recycle bin.

The aluminium is then collected and taken to a treatment plant.

In the treatment plant the aluminium is sorted and cleaned ready for reprocessing.

It then goes through a re-melt process and turns into molten aluminium, this removes the coatings and inks that may be present on the aluminium.

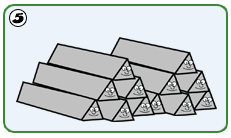

The aluminium is then made into large blocks called ingots. Each ingot contains about 1.6 million drinks cans.

The ingots are sent to mills where they are rolled out, this gives the aluminium greater flexibility and strength.

This is then made into aluminium products such as cans, chocolate wrapping and ready meal packaging.

In as little as 6 weeks, the recycled aluminium products are then sent back to the shops ready to be used again.